By the middle of the 19th century, political economists agreed that slavery was archaic as well as brutal, unprofitable as well as unconscionable. They were inspired by an idea of “the market,” an idealized economic space governed by natural laws as immutable as entropy or gravity. The market treasured the right to freely sell one’s labor; the market abhorred slavery. But on the eve of the war of the rebellion in the United States, Southern slave owners argued that slavery was the future. In the industrial areas of the northern United States and western Europe, battles for fair wages and better conditions had been contests over the definition of “freedom” within the strictly regulated and heavily capitalized confines of factory work. “Wage slavery” was the opposite of a good working-class job. And yet, although most enslaved African Americans did agricultural labor, tobacco processing plants in the Upper South, iron foundries in Alabama, and a wide range of other industries employed more and more unfree people.

In 1851, De Bow’s Review, a leading journal of the slave-owning class, published a lengthy essay on the “Future of the South” that set out a plan to accelerate this marriage of industrialization and slavery. Cotton, the essay noted, was Britain’s most important manufacturing sector, the cornerstone of the most advanced industrial economy on earth. Cheap cotton cloth had become a staple across Europe and the Americas. Easy to clean, easy to replace, more comfortable than wool, and much cheaper than silk, it had made life easier for millions. The essay posited that although the factories that turned raw cotton into finished cloth relied on free labor, the raw material itself had “bound the fortunes of American slaves so firmly to human progress, that civilization itself may almost be said to depend” upon the preservation of slavery. The essay acknowledged that the Atlantic and the Mason-Dixon separated the slave power from the mills of Manchester and Massachusetts. However, mechanization seemed to promise a dramatic reduction in the number of people required for agricultural labor, freeing up an enslaved industrial workforce. As cotton refineries and cloth factories sprouted in the South, the entire Mississippi Valley would become a giant factory and New Orleans would become Liverpool, “communicating by the father of waters with that vast region which is to be the Manchester of the world.”

The marriage of slavery and factory work proposed in De Bow’s Review might seem incongruous. After all, the story that many white Southerners told themselves after the defeat of the slaveholders’ rebellion was one of a gallant agrarian South crushed by a relentless, soulless industrial North. But on the eve of the war, Northern and Southern businessmen were more frank about the intimacy of free labor and slave labor in the United States. In 1860 Edward Bean Underhill, a prominent British missionary, visited Cuba, where men from both sides of the sectional divide were staying at his hotel. A Southerner told him, “The North depends on the cotton growers of the South”; a Northerner told him, “The South depends on the North for capital, and even for existence.” The meeting itself says something more: Investors from free and slave states alike were keen to sink money into profitable Cuban sugar plantations, worked nearly exclusively by enslaved people.

Moreover, the word “factory” itself was connected in its etymology to the slave trade. In the early modern era, distant commercial outposts were known as “factories,” after the “factor,” the presiding merchant. The most notorious “factories” were the castles and prisons operated by Europeans on the coast of West Africa, where the African slave trade met the transatlantic slave trade, and whence many millions of enslaved people began the Middle Passage to the Americas. In Behemoth: A History of the Factory and the Making of the Modern World, Joshua B. Freeman doesn’t dwell on the bleak fantasies of slaveholders or the connections between early-modern colonial slavery and the rise of industry. And yet, when he argues that the history of factories can make concrete the inchoate “ties between coercion and freedom, exploitation and material advance” inherent in industrialization, he is tapping into something essential about the relationship between forced labor and free labor. The “Future of the South” displayed many of the features of what Freeman calls “industrial gigantism,” a pattern of industrialization through massive, capital-intensive factories with workforces many times larger than the average. Moreover, industrial giants—like the idea of the “Manchester of the world” to slave owners—were symbols of the future. They seemed in their time to represent new models of production, and to employ a new kind of worker.

The book begins in the silk and cotton mills of England, moves to the American cotton and iron industries, hops to the Soviet Union’s massive investment in heavy industry from the 1920s to the 1940s and back to the deindustrializing United States after World War II. The book ends in Vietnamese garment sweatshops and Chinese electronics factories. These industries, Freeman admits, and the people who worked in them, were only rarely representative of the overall shape of industrialization or of the employment and composition of the working class. However, the industrial giants seduced politicians, artists and writers, who visited and documented the portentous, unsettling newness of vast buildings and new kinds of workers. The workers themselves, organized into ever larger units, doing ever more specialized and interdependent tasks, found new sources of solidarity within the walls of giant factories. Workers in the cotton industry in England, “factory girls” in New England, or sweat-soaked steelworkers in the United States became, Freeman argues, symbols of the “future shape of society,” for better or worse.

Freeman notes the tendency of industrial giants to consolidate. The massive war chest and vast physical plant of J. P. Morgan’s U.S. Steel show the way industrial gigantism could effectively make an entire region into a single interconnected factory complex. But it is the auto manufacturers of the early 20th century that seem best to represent the aesthetic ambitions of industrial gigantism. Henry Ford, Freeman shows, was not only a modern industrialist but a modernist. His factories, and especially the enormous Dearborn and River Rouge plants, were monuments to his faith in the commercial advantages of vertical integration and to his aesthetic preoccupation with autarky. Ford plants had their own docks and depots, receiving iron ore and other raw materials shipped across the Great Lakes. They had their own glassworks, their own blast furnaces, their own rubber refineries, their own machine shops. Behemoth frames the era of the great car manufacturers as the high-water mark of industrial gigantism in the United States. The desire of industrialists to control every aspect of manufacturing was checked by the tendency of megafactories to unionize. As the heroic 1937-38 sit-down strikers at General Motors’ megafactory in Flint, Michigan, showed, if workers stopped the assembly line they could stop every aspect of production. The postwar era was marked by decentralization of manufacturing as globalization made it easier and less expensive to subdivide production, and to atomize and isolate unionized workers.

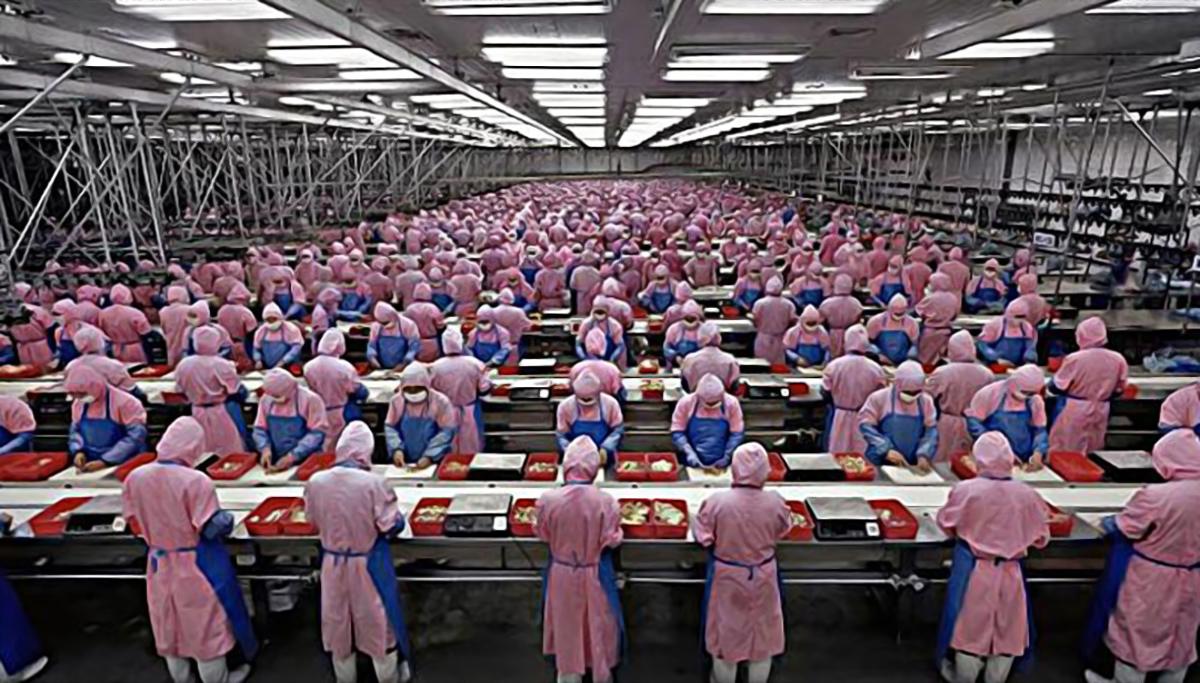

In his final chapter, on China and Vietnam’s vast electronics and clothing factories, Freeman posits the end of the future. In postindustrial countries, the development and production of new products are wholly separate. Engineers for Apple, for example, might work in California while iPhones are assembled in China, from parts purchased from dozens of other countries. The Asian megafactories conform to many of the features of “industrial gigantism.” Established largely as experiments in free-market enterprise, in special economic zones with strict residency requirements, many Chinese and Vietnamese factories are built on a scale that can stun visitors unused to the realities of manufacturing in the 21st century. For example, the Longhua Science & Technology Park, one of the main operations of the notorious electronics firm Foxconn, has a workforce of between 300,000 and 400,000. The factories pull in the children of farmers from rural areas, offering new material wealth in exchange for submitting to a radical transformation of the experience of time and labor. However, Freeman argues that these factories are no longer futuristic or exceptional; industrial gigantism has become the rule.

What Freeman is describing is the process of the unnatural becoming naturalized; of hellish work in “dark Satanic mills” becoming an idealized working-class job; of outsourcing and threats to cut wages becoming “blue-sky thinking” for a class of consultants; of complex, sinister, and obscure supply chains becoming a logistics industry. The risk of writing a history of the previously unthinkable becoming natural is that the author unconsciously acts as midwife to the process. Freeman is a careful historian, and Behemoth is a powerful, propulsive, and unsettling book. But the indefinite article in the subtitle of Behemoth carries a heavy load; this is a history of the factory. Historians make choices in framing their work. However, by locating the history of industrialization inside the walls of factories that he admits are exceptions to the general rule, Freeman risks erasing important aspects of the legacy of the “factory system” on the world we live in.

For one thing, a focus on American industrial giants—mostly in the Northern states, often with powerful unionized workforces—risks concealing the profound racism written into the logic of industrial capitalism. The idea of the slaveholding South as a futuristic “Manchester of the world” was part of the modernity of racism, capitalism, and slavery in the 19th century, just as vicious hostility to immigrants and profoundly racialized inequality is part of postindustrial modernity. Freeman notes in passing that after the Civil War, African Americans moving north from former slave states were sometimes employed as scabs to break strikes in steel mills, and that African Americans worked the steel mills of the segregated South. All workers were victimized by exploitation, but endless comparisons with slavery allowed white workers to invent and nurture their own sense of racial victimhood. The idea of a “white working class” with a special claim to protection and representation was forged as factory owners exploited cheaper immigrant and African-American labor, dividing workers on racial lines.

Moreover, the focus on giant factories risks portraying working-class history as a march of triumphant masculinity. Factories in the cotton industry initially employed mostly women and children, but the rise of legislation for better working conditions made “traditional” working-class jobs into jobs for male breadwinners. “Women’s work” was low-pay and low-status work—as working-class jobs became more desirable, they became jobs for men. By turning labor history into factory history, the victories of labor in female-dominated industries like teaching and nursing are written out. Freeman does not endorse in any way a whitewashed, overwhelmingly masculine history of labor. But the history of industry from within the walls of iconic, futuristic factories treats the exceptional as normal.

The Behemoth in the book of Job is a creature so vast that it eats entire grasslands and drinks up rivers to satisfy its hunger and thirst. Behemoth, God tells Job, is so powerful that only He, its creator, could destroy it. The Behemoth was a natural thing of unnatural power. Behemoth echoes Job; Freeman has written a kind of natural history of the giant factory. It arrived as a shock, pulling in new kinds of workers who had once been outside the labor market. These new workers suffer through brutal exploitation, eventually winning incremental improvement in working conditions through the solidarity encouraged by working in interdependent jobs at close quarters. Inevitably, the cost of running a massive factory and the massive capitalization required by its physical plant makes factory owners cautious and conservative. As revenues decline, giant factories either close or relocate, leaving behind wrecked buildings and wrecked lives. In medical terms, “gigantism” is pathological growth, and the pattern Freeman ascribes to factories evokes the bloom of algae and jellyfish in ocean ecosystems thrown out of balance—frenzied proliferation followed by collapse.

The idea of the natural rise, fall, and recrudescence of factories is compelling. But cycles of life and death have a compelling logic—that is everyone’s history, so it is easy to project it onto the history of things that aren’t biological. If anything, factories emerge from Behemoth as pathogens that flourish on the frontiers of global capitalism. And yet, biological metaphors have limitations. Parasites are ecologically complex. The protozoan that causes malaria in human beings requires a startlingly sophisticated and precise sequence of transmissions, from mosquito to mammal to mosquito to reproduce. Natural history shows that you can’t understand a pathogen only by looking at the way its lays low human sufferers, the biggest and most visible of its hosts. Likewise, trying to understand the pathologies of capitalism by looking at its most spectacular eruptions has limits. Freeman argues that giant factories were parts taken as the whole, but by locating his history within their physical plant, he risks mistaking the most visible symptom for the disease itself.

To abuse the metaphor, diseases require particular conditions to thrive—untreated water, a ready source of host bodies. Industrial gigantism doesn’t seem like it can be unpicked from the imperial and colonial ambitions of industrial powers, from the ambitions of individual capitalists, from the surrender of governments and regulators, from the globalization of trade and finance concomitant with the hardening of national borders, or from the idea of the market itself. Treating giant factories as pseudobiological entities, or at least entities that obey natural laws, is by definition a way of naturalizing a very particular form of capitalist exploitation. To his credit, Freeman resists writing the history of factories as the history of capitalism. Behemoth can’t be a book about capitalism, Freeman argues, because the Soviet Union, particularly under Stalin, was also susceptible to the aesthetic allure and material promise of giant factories. The Soviet Union was communist, and although the wages paid to workers in the heavy industries of the Soviet industrial belt (excluding the thousands upon thousands of prisoners and exiles working in conditions of near-slavery) might not have been paid according to a logic of capitalism, they shared a disciplinary logic devised in the early days of industrialization.

The idea of the market as a reformatory, where the poor would learn prudence, good conduct and the other virtues of bourgeois liberalism warped into political economy as the power loom replaced hand-loom work in Lancashire, in the 1820s. Political economists reasoned that if workers were paid too little, they might threaten the comforts enjoyed by the wealthy. If they were paid too much, they would piss it away. In Lancashire, the beginning of the war with revolutionary France led to a surge in cloth prices, and high wages for craftsmen. By the end of the Napoleonic Wars, the arrival of massive factories had reduced many weavers to starvation, and pulled their children into factory jobs that did not pay a breadwinner’s wage. Neither feast nor famine was acceptable to economists. “Families which to-day might be seen gnawing a decayed cabbage-stalk to sustain life,” wrote a commentator, “would tomorrow be drenched in their former sins; provided tomorrow brought them the means of renewed sensuality.”

Freeman offers, in his conclusion, a ray of hope. He reminds us that factories, at the very least, show that “it is possible to reinvent the world. It has been done before, and it can be done again.” But with what tools? If the excesses of industrialization are a kind of natural—if pathological—phenomenon, a force majeure, it makes it too easy to forget that we still live in the world of the factory, but the malice, strangeness, and stupidity of it has become invisible to us. And the things made in factories have raised global living standards, making human lives longer and more comfortable. Is it possible to have all of the things made possible by factories without tacitly submitting to the “factory system”? Freeman doesn’t answer that question; good historians don’t predict the future.

Behind the history of the factory is an even bigger question—what does it mean to be “modern”? The newness and futurity of industrial giants, and the amount of stuff they produced, in a quantity and variety inconceivable to people living in a preindustrial age, seem to have a good claim to “making the modern world.” But modernity is more than stuff; industrialization is more than giant factories. A challenge of trying to “reinvent the world” is figuring out where to find purchase on the parts of the world that can be reinvented. Late capitalism, with its endless emphasis on work, its bruising geography of megacommutes and decaying public transit, its reduction of all kinds of valuable institutions—democracy, education, social welfare—to consumer choice, is gigantic in the way Freeman uses the word, so big that it is hard to see anything else. The paradox of this ambitious, thought-provoking book is that in order to understand the panoply of modernity, it is necessary to look at an enclosed space—to see the entire world from inside factory walls. The question that Freeman cannot answer is how to look beyond them.